The PVC pipe industry is an integral part of the VinylPlus® programme and is working to increase the recycling of PVC pipes across the EU. Collection schemes have been introduced and recycling undertaken through the European Plastic Pipes and Fittings Association (TEPPFA) with the support of Recovinyl.

Around 50,000 tonnes of PVC pipes are recycled each year through the VinylPlus® programme. Since 2000, 820,000 tonnes of PVC pipes have been recycled. In addition, 75,000 tonnes of recycled PVC is used in new pipes each year, for instance in three-layer sewer pipes with a core made of recycled PVC.

According to the latest Recovinyl Traceability Study, PVC pipes take up 11% of all PVC recyclate in Europe – the third largest application area for recycled PVC after windows and profiles (42%) and traffic management (12%).

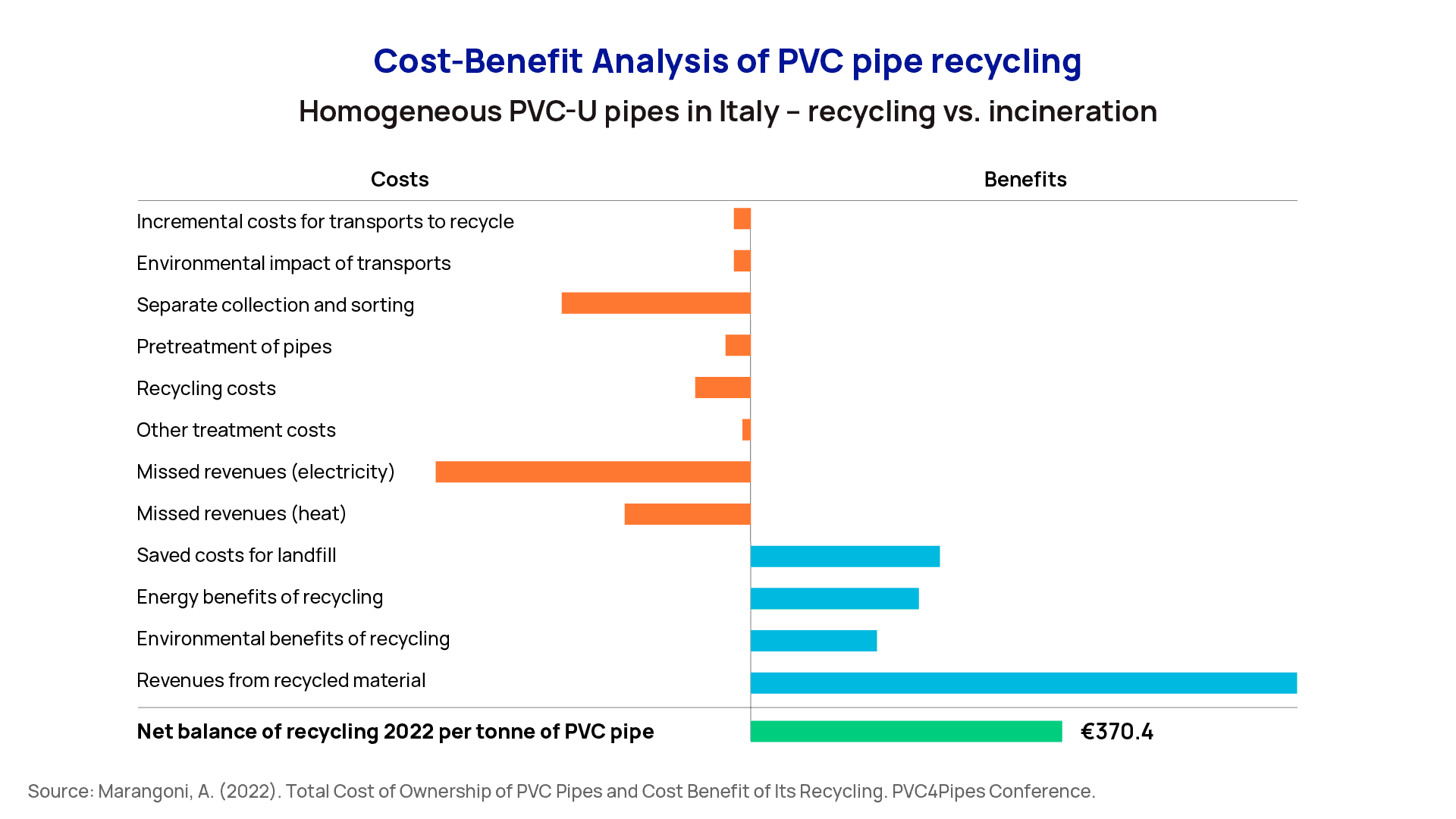

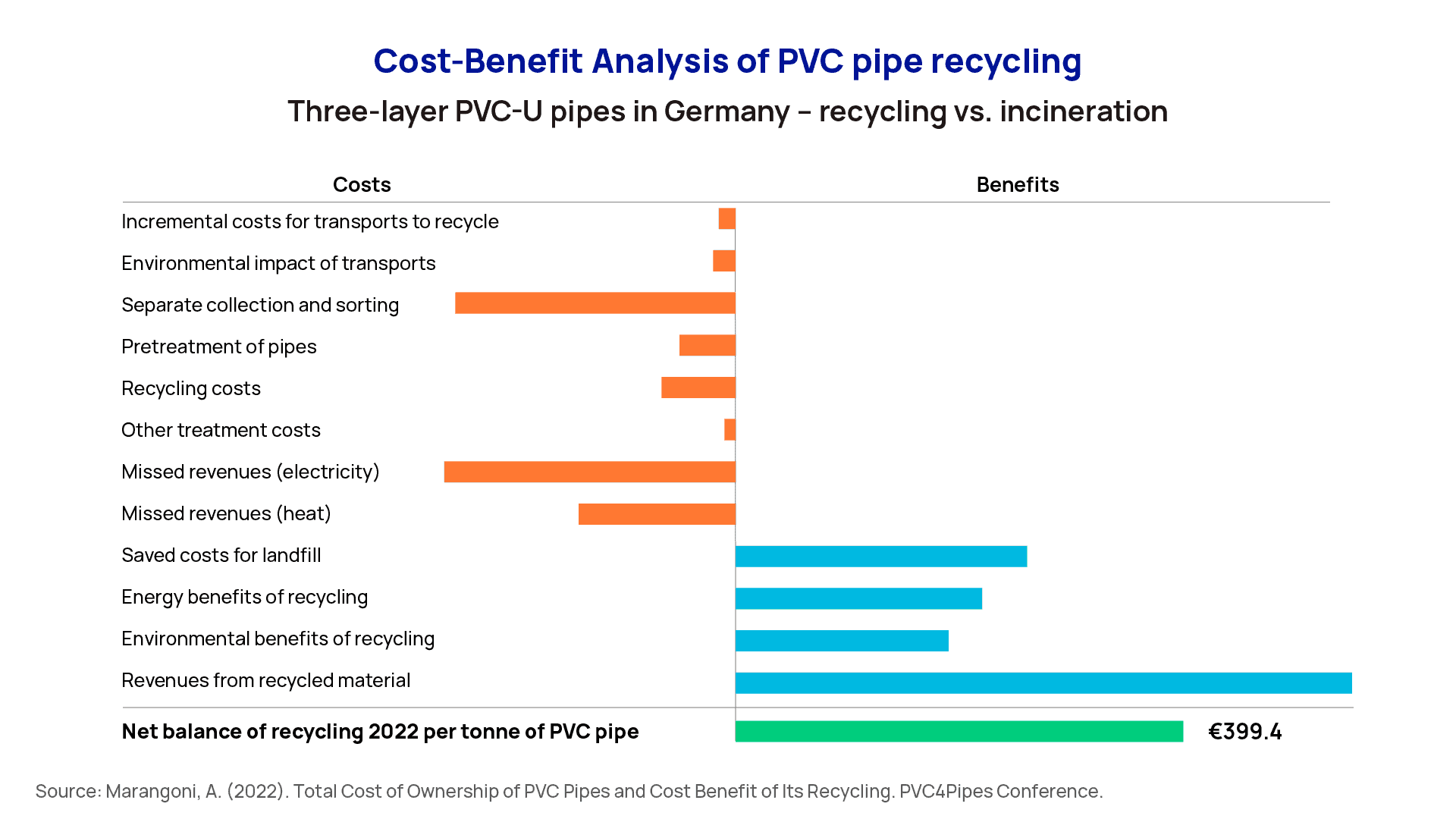

Cost-Benefit Analyses confirm cost benefits of recycling

Recycling not only contributes to creation of green European jobs and resource, energy, and carbon savings. Through the methodology of Cost-Benefit Analysis (CBA), it has been demonstrated that recycling versus incineration or landfilling yields significant cost benefits. Even as Europe grapples with the rise in energy costs, the economic rationale for PVC pipe recycling remains strong.

PVC pipes can be recycled up to 10 times

PVC is an easily recyclable plastic, and PVC pipes are no exception. PVC pipes and other rigid PVC products can be recycled 8 to 10 times without losing their technical properties. This is because the recycling process does not measurably decrease the chain length of PVC molecules. For documentation, see below:

- Fumire, J. & Tan, S.R. (2012). How much recycled PVC in PVC pipes? Plastic Pipes Conference XVI, Barcelona.

- Leadbitter, J. & Bradley, J. Closed Loop Recycling Opportunities for PVC. IPTME Symposium, Loughborough University, 3-4 November 1997.

- Frank, Andreas & Messiha, Mario et al. (2021). Slow Crack Growth Resistance of reprocessed PVC. Plastic Pipes Conference PPXX, Amsterdam.

- Yarahmadi, Nazdaneh & Jakubowicz, Ignacy & Gevert, Thomas. (2001). Effects of repeated extrusion on the properties and durability of rigid PVC scrap. Polymer Degradation and Stability. 73. 93-99. 10.1016/S0141-3910(01)00073-8.

Recycled PVC with lead permitted in new pipe manufacturing

In May 2023, the European Commission adopted a regulation aimed at restricting the use of lead in PVC products. It mandates a maximum lead content of 0.1% in all PVC products across the European market, including those that are imported.

Historically, European PVC pipe producers have been proactive in reducing lead usage in their products. This initiative began over 25 years ago, particularly in the Nordic countries, where producers voluntarily started phasing out lead-based stabilizsrs. This trend spread across Europe over the following decade, with a shift towards safer alternatives like calcium zinc or calcium organic-based stabilisers.

10-year derogation for pipes

A notable aspect of the new regulation is the 10-year derogation it allows for the use of recycled rigid PVC containing lead, specifically in the middle layer of multilayer PVC pipes, with the exception of those used for drinking water. These particular products are permitted to contain up to 1.5% lead. However, they must be clearly marked, and the source of the recycled material needs to be certified by third party.

The regulation also specifies that 'lead-free' recycled rigid PVC, defined as having less than 0.1% lead content, is exempt from these new restrictions. This exemption allows PVC pipe manufacturers to continue using this material without any specific marking requirements, regardless of its origin.

Closed-loop recycling for profiles and sheets from May 2026

Additionally, the regulation introduces a closed-loop recycling obligation for lead-containing rigid PVC recyclate derived from profiles and sheets. There is a transition period extending until the end of May 2026 for this requirement. Post this date, manufacturers will be prohibited from using recycled material containing lead from PVC profiles and sheets in the production of multilayer PVC pipes. This three-year transition period is designed to give manufacturers time to enhance their collection schemes and increase the use of end-of-life PVC pipes in manufacturing.

Circular economy of PVC pipes in Europe

Discover how the European PVC and PVC pipe industry is contributing in the animation from TEPPFA and VinylPlus.