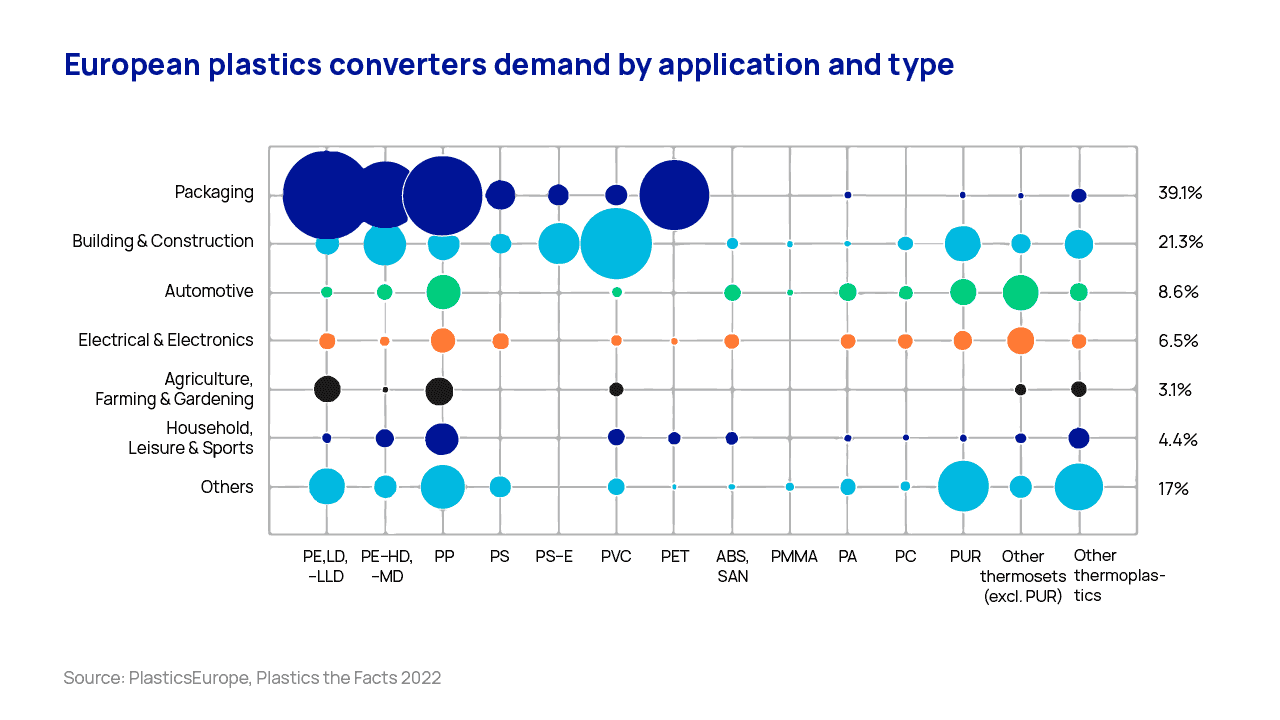

Polyvinyl chloride, also known as vinyl or simply PVC, is the third-most produced plastic in the world. Due to a combination of versatility, unique technical properties, recyclability, and affordability, PVC is used for an endless variety of applications from life-saving blood bags and other medical devices over credit cards to cinema projection screens.

Yet PVC is primarily a building material: 70% of all PVC produced in Europe goes into windows, pipes, flooring, roofing membranes, cables and other building products. In fact, PVC is by far the leading plastic in the European building and construction market.

The PVC and PVC piping industry's contribution to European economy

To the moon and back

‘Pipes and fittings’ is the second-largest PVC application market, for which 24% – or around 1 million tonnes – of PVC produced in Europe is used. Durability, superior long-term stiffness and high strength to weight ratio are some of the key reasons to use PVC for pipes. Examples of PVC piping applications are water supply, sewage and underground drainage, rainwater systems, hot and cold water applications, and industrial piping networks.

PVC pipes are usually divided into three categories, each with their own technical advantages: PVC-U (unplasticised), PVC-O (molecular oriented) and PVC-C (chlorinated). Fun fact: if all the annual European PVC pipe tonnage was converted into a 110 mm drain pipe at 1.7 kg/m, it would equal to 735,294 km, which is the distance to the moon and back.

Pipes for a sustainable future

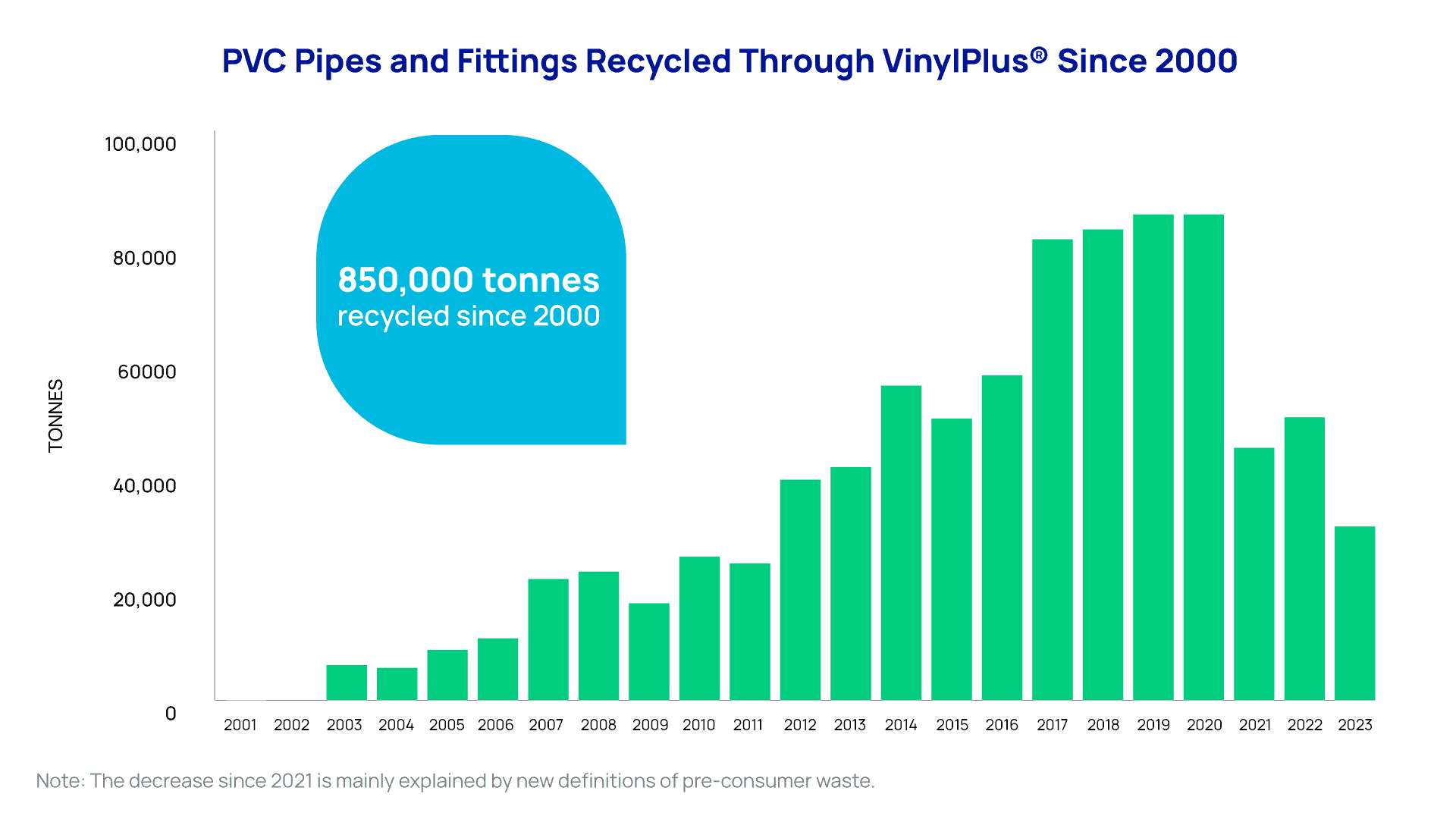

PVC products in general and pipes in particular are very well suited to be part of a sustainable future. The plastic has always been regarded as a low-carbon polymer, made from 57% common salt and only 43% oil or natural gas. PVC is easily recyclable and can be recycled mechanically several times without loss of technical properties. 850,000 pipes and fittings have been recycled since 2000 through VinylPlus®.

Moreover, bio-attributed and circular-attributed certified PVC resins are increasingly available on the market thanks to innovation by the industry. By choosing bio-attributed and circular-attributed PVC, huge CO2 savings can be achieved. An example is the construction of a fossil-free pre-school in Gothenborg, Sweden, where the piping system is made from bio-attributed PVC that provide CO2 savings of 90% compared to conventional PVC.

years of service life for underground PVC pipes

PVC pipes recycled in Europe since 2000

The European PVC Industry is committed to sustainable development

The circular economy, sustainable development, and resource efficiency are concepts that have long been part of the European PVC industry's focus and remain at the top of its agenda. For over two decades, VinylPlus, the commitment to sustainable development within the European PVC industry, has been a key contributor to the circular economy by driving continuous growth in PVC recycling.

Since 2000, more than 8.8 million tonnes of PVC have been recycled through VinylPlus, including 850,000 tonnes from PVC pipes and fittings. Recycling 1 kg of PVC prevents 2 kg of CO2 emissions, meaning VinylPlus' activities have saved over 17.6 million tonnes of CO2 since 2000. PVC recycling also supports the creation of thousands of green jobs in Europe while promoting energy and resource savings.